The Automatic High Pressure Steam Sterilization Machine is a top loading sterilizer which provides safe, reliable, and automatic controlling sterilizing equipment for food industry. It is equipped with heater, disinfection tube, container tube, safety valve, releasing steam valve, pressure temperature indicator, and sterilization end alarm, and the device of automatically cutting off the power ect. […]

V Rotary Powder Mixer

V Rotary Powder Mixer is suitable for mixing chemicals, food, medicine, feed, ceramics, metallurgy and other industries powder or granule-like material. Aircraft structure is reasonable, simple to operate airtight, easy access to materials, (manual or vacuum feeding) cylinder made of stainless steel for easy cleaning, it is one of the basic equipment of enterprises. The […]

Take Away Conveyor

Take Away Conveyor is used to send packed finished bag after-packing detecting device or packing platform. Take Away Conveyor is covered with 304SS frame, which is stable, reliable and good appearance, also belt and chain plate is optional. Features No damage to material, easy to clean Adjusting the transmission speed according to customers’ demand and […]

Slice Cutter Machine

This meat slicer machine’s plate is made of stainless steel. It conforms to the international food hygienic standard and can cut pork, mutton, beef , gammon and fish into the same thickness slice. It can also cut jellyfish , kelp , pickle and sauerkraut and so on. The machine has the advantages of excellent design, […]

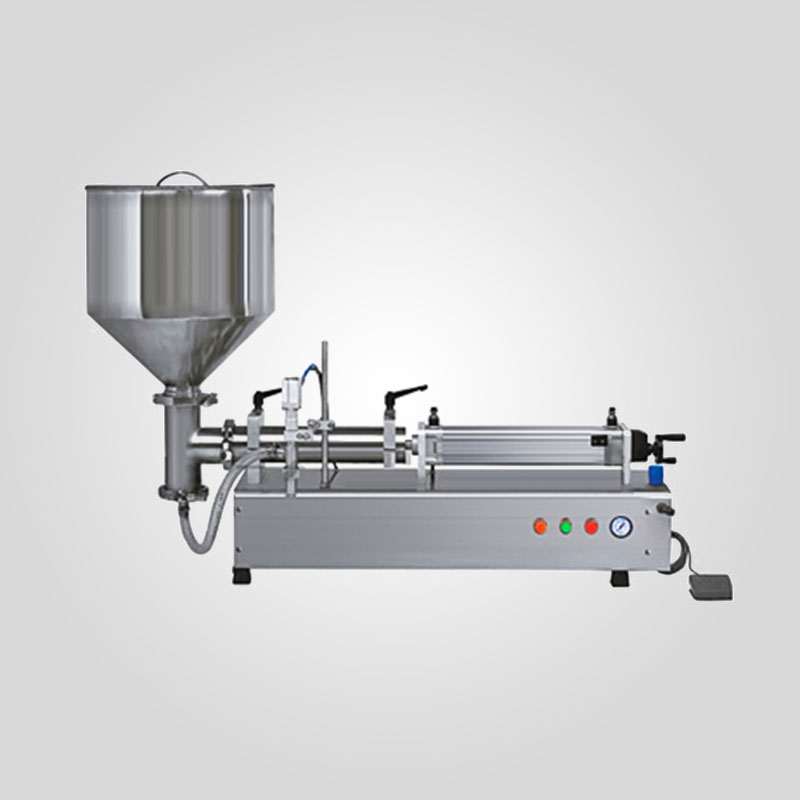

Semi Auto Liquid Filling Machine ( Piston Pump )

Semi Auto Liquid Filling Machine ideal for the packing of filling products at any kind of liquid. Semi Auto Liquid Filling Machine is engineered to be used in pharmaceutical, food processing, chemical, cosmetic, and allied industries for filling liquid items into plastic pouches, bottles, vials and other products. All the contact components and parts are […]

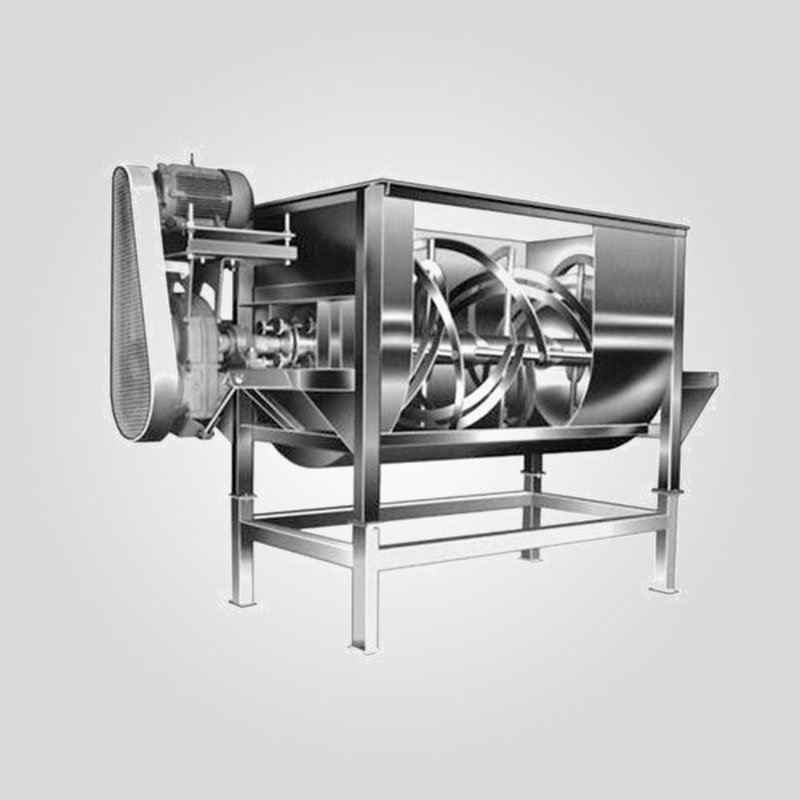

Rotary Drum Mixer

The Rotary Drum Mixer performs complex movements so as to complete uniform mixing. This mixing equipment is highly versatile and suitable for a variety of materials through its disseminating, agglomerating and mixing functions. This machine is widely used in the pharmaceutical, chemical, food, metallurgical, light industry and various scientific research units and institutes. It can […]

Powder Ribbon Mixer

A Ribbon blender or a mixer is a high tech machine that comprises a U- formed horizontal trough together with a single or double helical ribbon agitator that rotates within. This agitator channel is positioned within the center of the container.With the usage of progressive technology and innovative machines, we offer Powder Ribbon Mixer, which […]

Mineral Water Packaging and Processing Line

The 5 gallon water bottling machine ,including Water treatment system / Decapping machine / Inside brusher / Externer brusher / Automatic 5 Gallon rinsing filling capping machine / Automatic Cap sleeve label machine / Code sprayer / Film wrapping machine / Automatic 5 gallon palletizer system . The filling line specially for 3-5 gallons barreled […]

Meat Slicer Machine

General’s GSE series commercial meat slicer is compact, saving you space, with standard features usually found only in heavy-duty slicers. General’s meat slicer is designed to slice meats and cheeses, perfect for smaller light- to medium-duty foodservice businesses, including restaurants, diners, delis, specialty shops and more. This slicer machine offers chefs the reliability, quality and […]

Linear Liquid Filling Machine

Automatic Linear Water Rinser is used to remove dust particles and other dry contaminants from clean containers. Typically used in the bottled water industry, this Water Rinser can also be utilized in a variety of other industries that require rinsed containers prior to filling. The containers are automatically indexed into the Rinser. The grippers capture […]

Fully Auto Bean Curd Making Machine

Fully Auto Bean Curd Making Machine was developed in accordance with the principles of traditional yuba formation,and through a series of first-line production market research and experimentation. The whole machine is made of high quality 304 stainless steel, which is safe, reliable and durable! The unique floating technology at the bottom of the pot enables […]

Food Fryer System

The Food Fryer System Machine and heat exchanger are individually sized to fit your products’ heat load and production needs, so you never have to buy a larger fryer than necessary based on how many heating elements will fit in the pan. In order to reduce installation costs, oil filters, pumps, piping and an oil […]